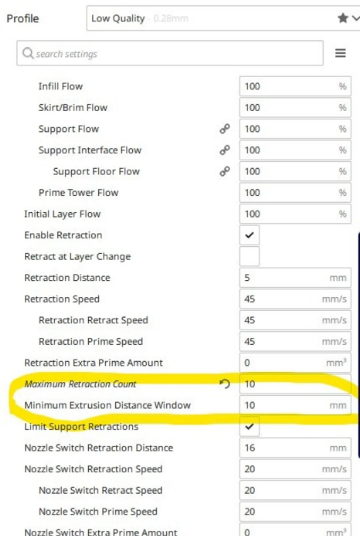

If you’re still noticing stringing after modifying each of these values, chances are your filament is being heated to too high a temperature. MatterHackers did a great experiment adjusting values like retraction distance, retraction speed, and travel speed, and you can find those results here. Their experiment found that 150mm/s was an ideal travel speed for many machines. Most slicers have a variable named ‘travel speed for non-print moves’ which can be modified to adjust the speed at which your nozzle travels across empty spaces. The faster your nozzle travels across empty spaces, the less time there is for filament to ooze out of the nozzle. More exotic materials like TPU often require slower retraction speeds and greater retraction distances. Bowden setups typically benefit from speeds in the range of 30mm/s – 50mm/s and distances around 2mm. Materials like PLA and ABS tend to work well with a speed of 40mm/s – 60mm/s and a distance of 0.5mm to 1mm on direct drive setups. Next, identify which filament you’re using as different materials require different retraction settings. To determine your optimal retraction values, first consider whether you’re using a bowden or direct drive extruder. Direct drive extruders will typically require a lower retraction distance than bowden extruders. These can be powerful tools to further dial in your retraction values, and consult your specific slicer to see how they’re used. Some slicers also include special ‘coast’ and ‘wipe’ parameters. A distance that’s too low will fail to prevent strings from covering your prints.ĭialing in the retraction distance and speed values in your slicer is the best thing that can be done to combat stringing. Image Source: Simplif圓D.comĪ distance that’s too high will cause blobs in your print and lead to filament jams.

0 kommentar(er)

0 kommentar(er)